BVLGARI SHAPES THE FUTURE OF ITALIAN JEWELRY IN VALENZA

Published on 11.25.2025

6 minutes

- Hall of Fame

- Design & creation

- Savoir-faire

- Heritage

- Watches & Jewelry

At the heart of Italy’s jewelry capital, Bvlgari’s expanded Valenza Manifattura unites artisanal mastery, sustainable innovation, and education, shaping the future of high jewelry.

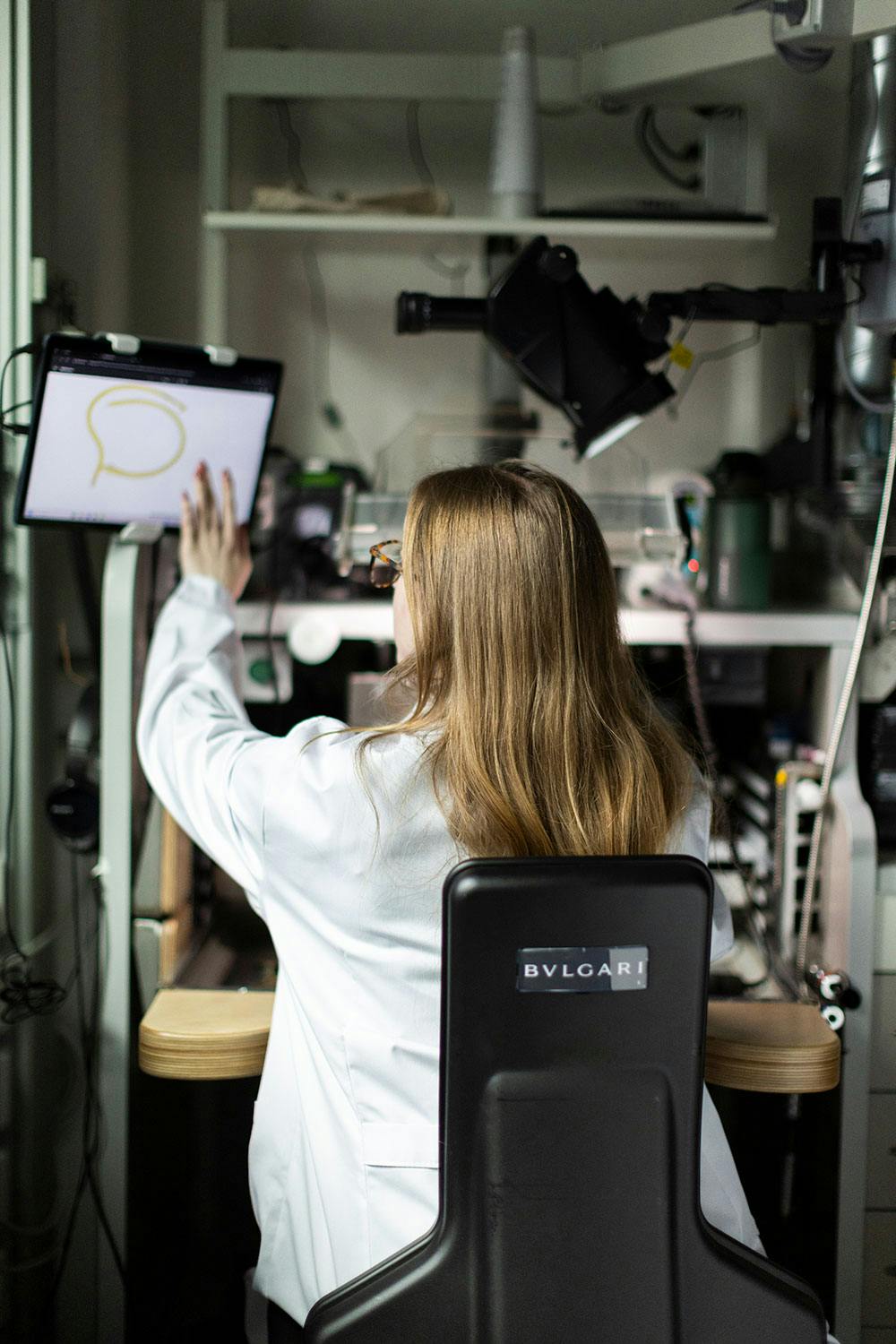

In Valenza, Piedmont, the historic city of Italy’s goldsmithing tradition, Bvlgari has created a true workshop of excellence. The expanded Manifattura Bvlgari, now the world’s largest single-brand jewelry manufacturing facility, reflects the Roman Maison’s ambition to preserve and reinvent Italian jewelry craft. Spanning 33,000 square meters, artisans, engineers, and designers collaborate to bring to life pieces that combine technical mastery with timeless creativity.

Since its opening almost a decade ago, the Manifattura has stood as a symbol of Bvlgari’s vertical integration strategy, uniting every stage of the creation process – from precious metals to gemstone setting – under one roof. Over 1,100 artisans from more than thirty nationalities now practice their craft on site, united by a shared pursuit of excellence. The facility plans to welcome more than 500 additional artisans in the coming years, doubling production capacity while ensuring the transmission of centuries-old expertise.

At the heart of the complex, the Scuola Bvlgari marks a key milestone in the Maison’s commitment to training the next generation. The first publicly accessible Bvlgari jewelry school, developed in partnership with Italy’s Tarì Design School (TADS), offers professional training in goldsmithing and gemstone setting alongside master artisans. Connected to the historic buildings via a suspended walkway, the school embodies the link between tradition and innovation, bridging heritage techniques and contemporary methods.

The Valenza Manifattura is also a statement in environmental responsibility. LEED Gold-certified, the site meets nearly half of its energy needs through on-site renewables, including more than 4,100 photovoltaic panels, while the remainder comes from 100% renewable sources. The surrounding 8,000-square-meter grounds have been rewilded with native trees, and ten beehives housing nearly one million bees support local biodiversity. Since 2022, all Bvlgari jewelry is crafted with RJC CoC-certified gold, ensuring complete traceability and adherence to ethical standards.

More than a production site, the Manifattura is designed as a living, human-centered space. Bright, open workshops, lounges, a restaurant, concierge services, and employee wellness programs reflect the Maison’s philosophy: true excellence flourishes in an environment that nurtures creativity and well-being. As Bvlgari CEO Jean-Christophe Babin notes, “The Valenza Manifattura embodies the Brand’s holistic vision, combining environmental responsibility, knowledge transmission, and employee fulfillment.”

At Valenza, Bvlgari harmonizes Italian artisanal mastery with modern technology in a space that is both sustainable and inspiring. The facility exemplifies the Maison’s belief that luxury is not only about creation – it is about preservation, innovation, and transmission. From Rome to Valenza, from generation to generation, Bvlgari continues to embody the beauty of craftsmanship and the future of jewelry.